A revolutionary, planet-saving enzyme

- Home

- Swallow Green

- A revolutionary, planet-saving enzyme

A revolutionary, planet-saving enzyme

- access_time11 May 2020

- account_circleSwallow Green

Utilizing an enzyme discovered within composted leaves, scientists are now breaking down plastic all the way into an easily recyclable form in a matter of hours. Carbios, the French company responsible for this new breakthrough, is already collaborating with Pepsi and L’Oréal, to name a few, to start an industrial market-scale production of the new substance within five years.

“We are the first company to bring this technology on the market. Our goal is to be up and running by 2024–2025, at large industrial scale.”

Deputy chief executive at Carbios, Martin Stephan

Their discovery, which is described as a major advance, joins an arsenal of possible solutions for plastic pollution control that have appeared over the last decade.

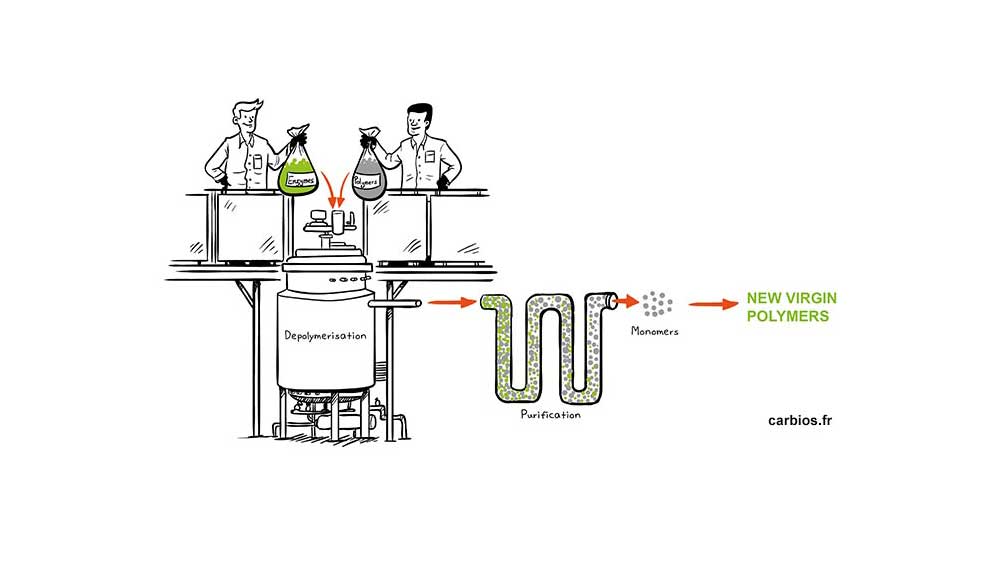

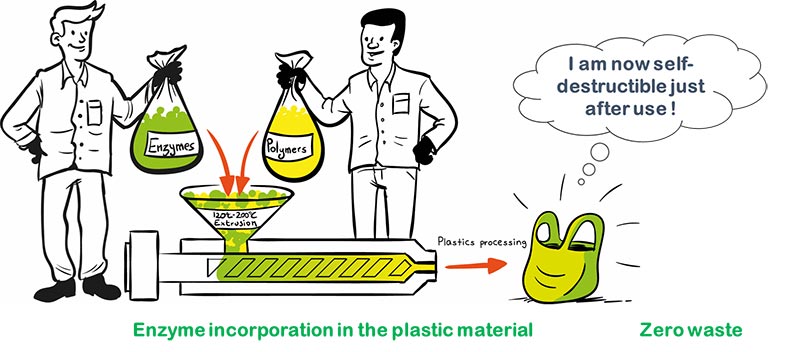

Image source: carbios.fr

Just like Boyan Slat, who famously chose to take on the Great Pacific Garbage Patch, or the bracelet folks at 4Ocean who took on the problem of ocean pollution in rivers, the scientists from the University of Toulouse are applying their breakthrough to another part of the problem, which is the recycling of plastic.

Plastic isn’t straightforward nor simple to recycle. There are common varieties of plastic made from multiple layers of different esters, each one requiring different equipment or temperature to breakdown. In addition to that, a lot of plastic esters that could be recycled, aren’t, because the value of the recycled material is so low, there is no way to financially sustain the operation.

The new enzyme achieves a minimum of 90% de-polymerization in mere 10 hours, meaning that the polymers, which are large complex particles, become monomers, meaning small single particles, in less than a day. What perhaps is even more amazing, they up as biologically depolymerized plastic that can actually be reused to recreate things like plastic bottles.

While manufacturing plastic bottles from recycled PET made by this enzyme would cost about 4% of the amount needed to make new bottles from fresh petroleum, the problem lies elsewhere. The recycling infrastructure, which includes the grounding up and heating processes applied to the plastic bottles before the enzyme is added would still make it more expensive in the end.

Nevertheless, the future is more than bright for this technology. Co-enzymes could and hopefully will be synthesized, companies must find a way to produce more inexpensive recycling infrastructure—both of which should finally bring down the cost of producing recycled plastic goods, drastically.

“These milestones reinforce our ambition to offer the market circular economy solutions that are both competitive and eco-friendly, and which will revolutionize the end of life for plastics and textiles.”

Deputy chief executive at Carbios, Martin Stephan