Plastic bottles to Cars

- Home

- Swallow Green

- Plastic bottles to Cars

Plastic bottles to Cars

- access_time30 January 2020

- account_circleSwallow Green

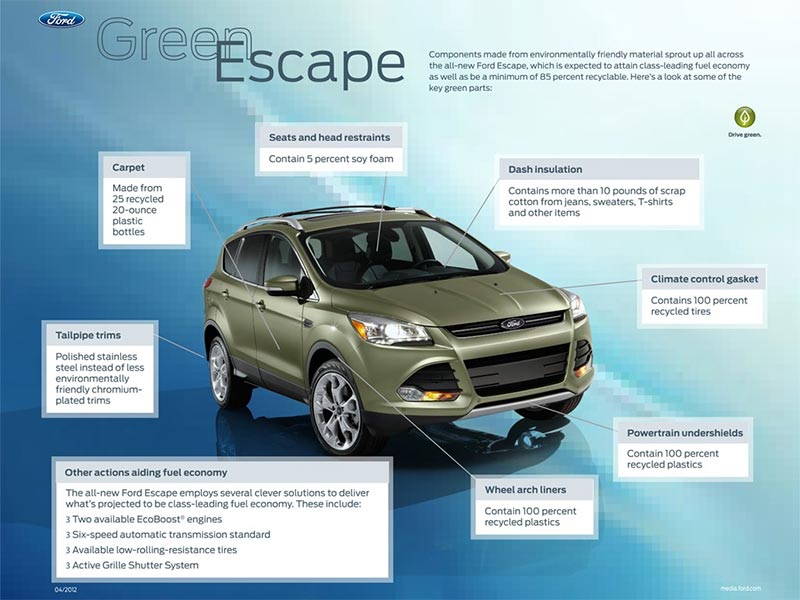

Ford Motor Company has been helping to promote the use of environmentally-friendly car parts. The revolutionary way they plan to do it is by using recycled plastic bottles to make carpets, underbody shields on all of their cars and SUVs, and wheel liners on F-Series trucks.

“The underbody shield is a large part, and for a part that big, if we use solid plastic, it would likely weigh three times as much. We look for the most durable and highest performing materials to work with to make our parts, and in this case, we are also creating many environmental benefits.”

Thomas Sweder, design engineer for Ford Motor Company

Image source: media.ford.com

In the past decade, the advancements made in aerodynamics have driven the need for underbody shields—and the global use of plastic parts in vehicles has grown exponentially, to meet this new need. Ford uses about 1.2 billion recycled plastic bottles per year—about 250 bottles per vehicle on average. Now, this is Ford on its own, the rest of the automobile industry are also using increasing numbers of plastic too.

The way it works is: thrown-away plastic bottles they are collected in thousands, from landfills and recycling lots, and are shredded into small pieces. These are typically sold to suppliers who turn it into fiber, by melting the bottle and extruding it. Those fibers are mixed together with other various types of fiber in a textile process and used to make a sheet of material which is formed into the automotive parts.

Due to its light weight and durability, recycled plastic is ideal for the manufacturing of underbody shields, engine under-shields, and front and rear wheel arch liners that help to improve vehicle aerodynamics. These shields reportedly also help create a significantly quieter environment on some of the new Ford models.

This is not the only way that Ford has been using recycled materials to benefit the environment. The automotive giant recently partnered with McDonald’s coffee suppliers to recycle all of their coffee roasting biowaste. They turn this byproduct into component used for the construction of their headlights.

Picture source: www.cnbc.com

“Ford is among the leaders when it comes to using recycled materials such as this, and we do it because it makes sense technically and economically as much as it makes sense for the environment. This material meets all of our robust specifications for durability and performance.”

Thomas Sweder, design engineer for Ford Motor Company